When you buy self-adhesive labels, you expect them to run smoothly on your label applicator, peel cleanly from the roll and keep your production moving, but when labels start snapping, tearing or causing downtime, the problem is often misunderstood.

One of the most common hidden causes is something called die-strike.

Understanding what die-strike is, and why a quality label manufacturer works hard to prevent it, can save you time, money and a lot of unnecessary frustration.

In label production, a cutting tool called a die is used to cut the shape of each label. The die should cut only through the label material (the face stock) and stop cleanly at the backing paper, also known as the release liner.

Die-strike occurs when the die is set too deep and cuts beyond the label material into the backing liner itself.

Instead of just separating the label, the die damages or weakens the liner underneath. This damage may be invisible at first but it compromises the strength of the carrier that holds your labels together on the roll.

Label dies don’t last forever. Over time they become worn and need to be:

Re-sharpened, or

Replaced altogether.

Both options cost money and normally this is the manufacturer’s responsibility.

However, in an attempt to extend the life of a worn die, some manufacturers increase cutting pressure rather than servicing the tool. While this might continue to cut the label shape, it also forces the blade into the backing liner — creating die-strike.

So instead of solving the problem properly, the liner is sacrificed.

A quality supplier maintains tooling correctly. A poor one pushes worn equipment too far.

Die-strike becomes most visible when labels are used on automatic labelling machines.

Because the liner has been weakened, it can no longer withstand the tension of the applicator. The result is:

Liner snapping

Labels tearing

Web breaks

Machine stoppages

Lost production time

To an inexperienced operator, this often looks like a labeller fault. And sometimes it is. But when die-strike is present, the machine is simply exposing a manufacturing defect in the labels.

In short:

Your applicator isn’t breaking the labels — the labels are already broken.

There are a couple of simple checks you can do on suspect labels.

If the liner snaps and the tear follows part of the label shape, that’s a strong indicator of die-strike. The tear is literally following the path of the over-cut die.

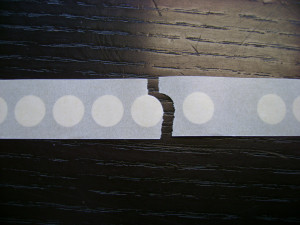

Take a short strip of labels and peel the labels off by hand. Then examine the bare backing liner.

If die-strike is present, you’ll often see:

Visible impressions

Score lines

Weak outlines of the label shape

A useful trick is to run a marker pen over the liner surface — it highlights the cut marks and makes die impressions much easier to see.

If you can see the label shape etched into the liner, the die has been set too deep.

And if that’s the case, the responsibility lies with the label manufacturer to remake the labels properly.

A professional label manufacturer doesn’t just sell labels — they control every part of the process to protect your production line.

A quality supplier will:

Maintain dies correctly

Re-sharpen or replace tooling when required

Set cutting depth precisely

Test labels under realistic machine conditions

Reject any work showing liner damage

They understand that a cheap shortcut in the pressroom becomes expensive downtime on your factory floor.

On the other hand, suppliers who ignore tooling wear, over-pressure their dies and skip inspection are effectively transferring their cost savings into your operational losses.

Die-strike doesn’t just damage liner — it damages productivity.

It leads to:

Stopped machines

Wasted materials

Operator frustration

Delayed orders

Higher overall costs

What looks like a small defect can quietly cost far more than the labels themselves.

Die-strike is caused when a cutting die is set too deep and damages the backing liner instead of just cutting the label. This weakened liner snaps under tension in automatic labelling machines, causing downtime that’s often wrongly blamed on the applicator.

By choosing a quality label manufacturer that properly maintains tooling and controls cutting depth, you protect your equipment, your workflow, and your bottom line.

Because good labels don’t just stick —

they run reliably, every time.

As a label manufacturer ourselves, Advanced Labelling Systems supplies quality self-adhesive labels for all labelling machines and they run correctly, without die-strike, because as a labelling machine supplier - we know labels.

Contact the ALS Consumables department for a quote or to order some samples.