A 3-roller wrap-around labeller is the best way to label large diameter cylindrical products with a long body label or to apply a label in registration to the weld seam of a can or other physical characteristic. The ALS 3-Roller Automatic labeller is modular and can be made for the labelling of filled or empty containers in sizes ranging from 250ml to 25 litres.

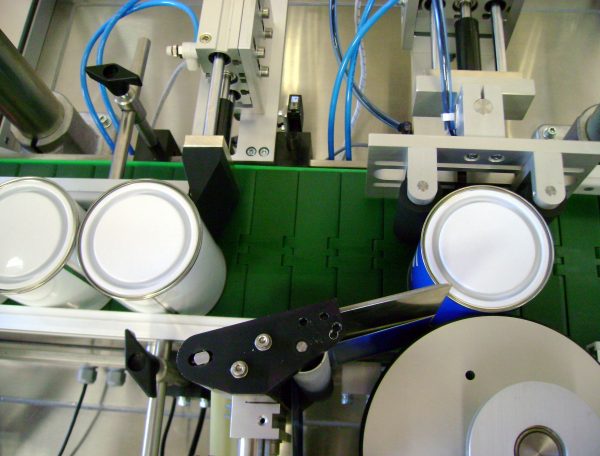

- Cans are transported along a heavy-duty low-friction slat conveyor and are controlled with a pneumatic gate that moves across the conveyor and holds the queue.

- The gate releases one can at a time.

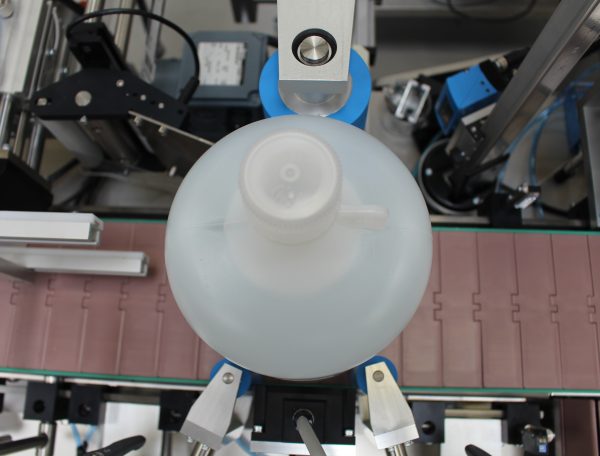

- When the can is released, it travels a short distance to the labelling station, where it is pushed against a large driven roller by two smaller, free-running rollers, that move in on pneumatic cylinders.

- Held between three rollers, the can cannot move forward.

- The driven roller spins the can and a sensor looks for the weld seam, after which, a signal is sent to the label applicator to dispense a label.

- The label is applied squarely and uniformly by the rollers, so that no spiralling or creasing occurs.

- The two smaller rollers are then retracted, which releases the can down the conveyor and then next can is then released automatically by the gate.

- A queue-back sensor at the out-feed determines whether there is a back-up of cans and will not release the next, until the queue-back has reduced.

Intuitive Control System

Electronic control: PLC with program selection, ensures quick setting and short change-over time.

From the selected program, the container labelling machine automatically makes the necessary settings of label position, handle lift and product detection.

On pre-decorated containers, the 3-roller labeller can detect front and back in the orientation unit.

Options

- Lid labelling

- Double dispenser for colour swatch and/or bar code label on larger product label

- 230 mm web width – allowing larger labels

- Automatic set-up of the machine

- Orientation unit and handle lifter

- Left/right hand execution