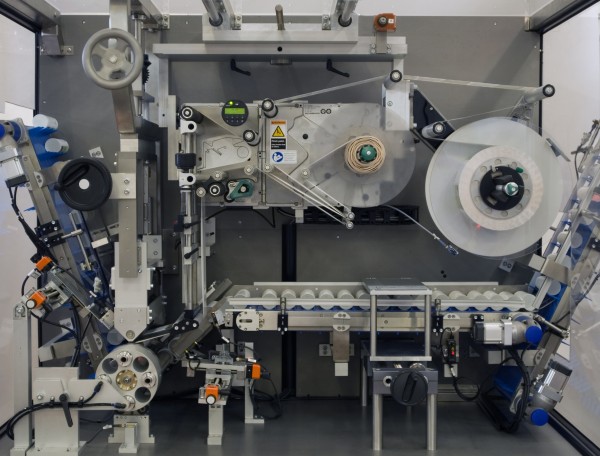

ALS Tube Labeller for Flexible Squeeze Tubes

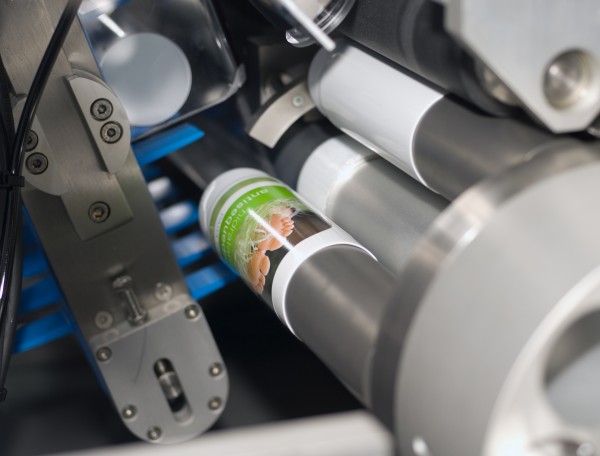

The ALS Tube Labeller series is a range of machines that apply self-adhesive labels onto flexible squeeze tubes, at high-speed and with great accuracy. The ALS T-Series are in use all around the World, by many leading manufacturers of personal care products and flexible plastic packaging manufacturers alike, who are all finding greater efficiency benefits of labelling squeeze-tubes with self-adhesive labels, over traditional screen printing.

All ALS tube labellers are custom built to meet the exacting demands of the manufacturers and suppliers. They can be used stand alone or integrated in-line, matching filling equipment speeds and one or two labels can be applied in registration. Our labelling machines are installed all over the world, including Europe, USA and Asia.

Benefits of Tube Labelling

- Low inventory of tubes

- Low wastage

- Low cost of tubes

- High quality graphics at lower cost

- Use paper, film or metalised labels

- Accurate product colour matching

- Tactile raised printing options

- Economic for short or long runs

The ALS T-Series Tube Labeller is suitable for plastic or aluminium tubes of circular profile and is capable of highly accurate and consistent label application at speeds in excess of 100 tubes per minute. Whether in-line or stand-alone, it’s modern design can be customised with a variety of optional equipment including barcode verification systems and automated in-feeds to satisfy a wide range of process or industry-specific requirements.

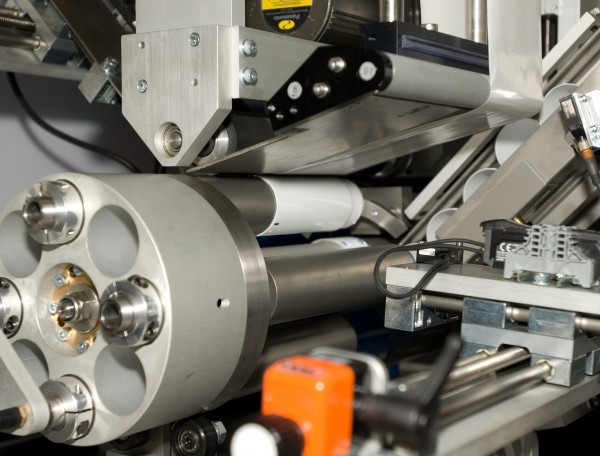

Every ALS T-Series machine is built upon a framework of steam welded, food grade stainless steel section. This solid foundation keeps movement and vibration to an absolute minimum to ensure consistent, accurate labelling.

Quick change-overs

The quick-release tube mandrel assemblies mean that the change-over from one tube diameter to another is just a single, one tool operation. As with our previous T-Series tube labellers, all user-adjustable items have precision digital indicators so everything can be quickly and accurately reset for repeat jobs.

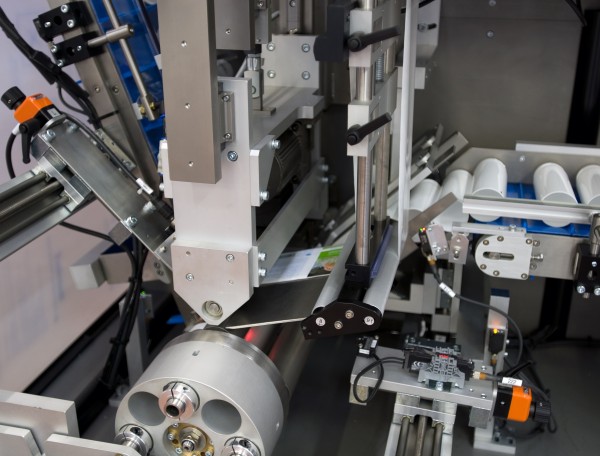

Accurate Label Placement

Working at speeds in excess of 100 tubes per minute, getting a label in exactly the right position every time is about knowing the precise moment to apply it. Using a range of sensing technologies the ALS T-Series gives operators complete control over the registration of single or multiple labels throughout 360° of the tube surface.