The ALS 306 and ALS 309 are the first of a truly unique range of modular automatic label applicators. They combine high-speed labelling with the highest accuracy to give you the ultimate labelling experience. The ALS 300 range offers a completely new modular concept. Routine maintenance has never been so easy!

High Performance Labelling Applicators – Suitable for all Production Lines

The ALS 306 and ALS 309 labelling machines offer extensive benefits and present new possibilities to industrial manufacturers and system integrators.

Our modular, flexible, high-speed labelling applicators are the perfect fit to existing production lines, are easy to maintain and will boost your run-time as they are designed for 24/7 production lines.

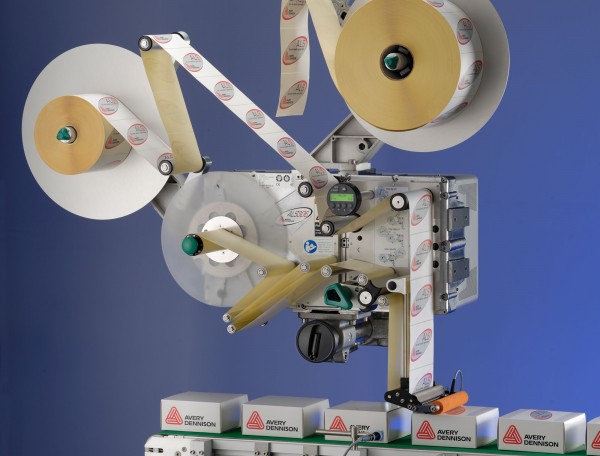

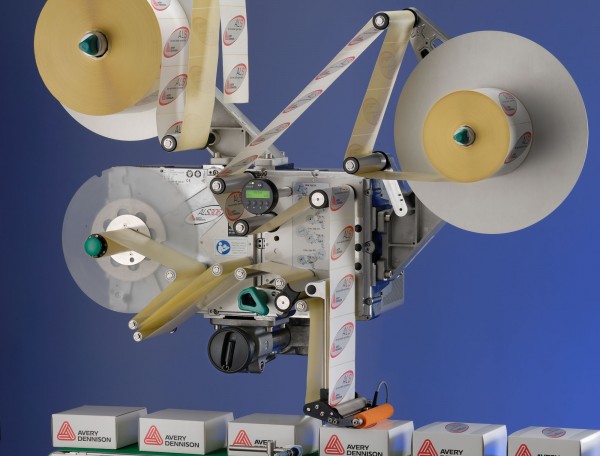

In particular, if you need to apply very large labels, then purchasing the ALS 306 will be a great asset to your business. This machine can easily handle 6” labels, and if you require even bigger, the ALS 309 model is for you – it has the capacity for up to 9” labels.

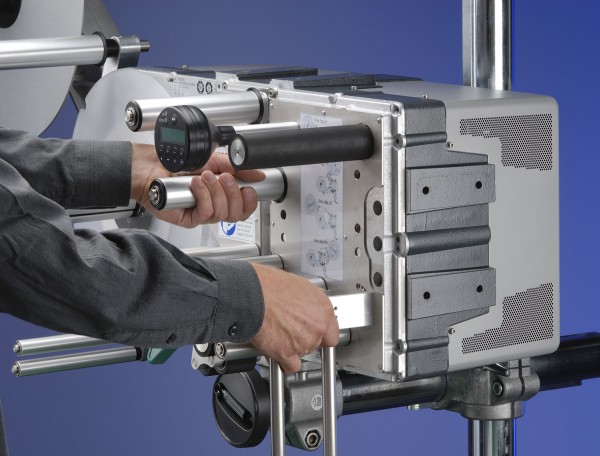

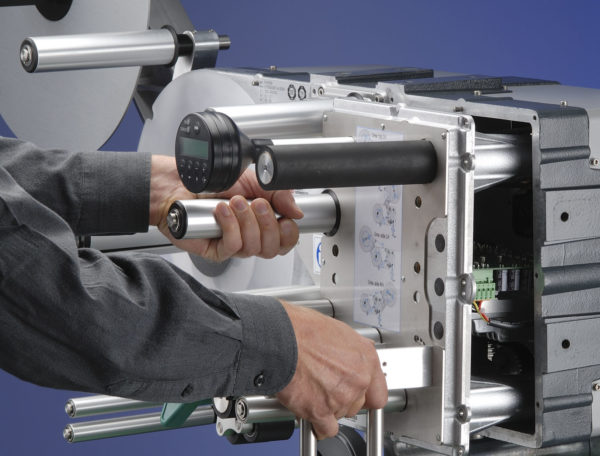

If you own or purchase the ALS 306, because of the modular concept, it can very simply be upgraded to an ALS 309 by changing the apply and rewind modules. This revolutionary design point future-proofs your initial investment.

Two labellers with some unique concepts…

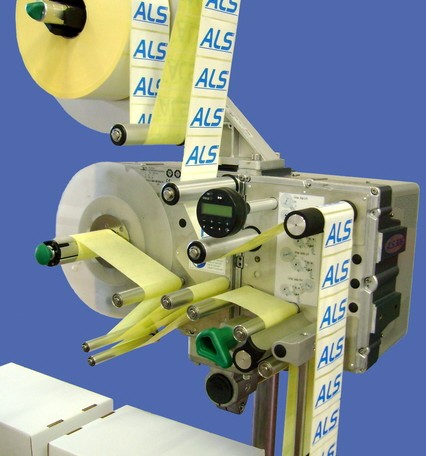

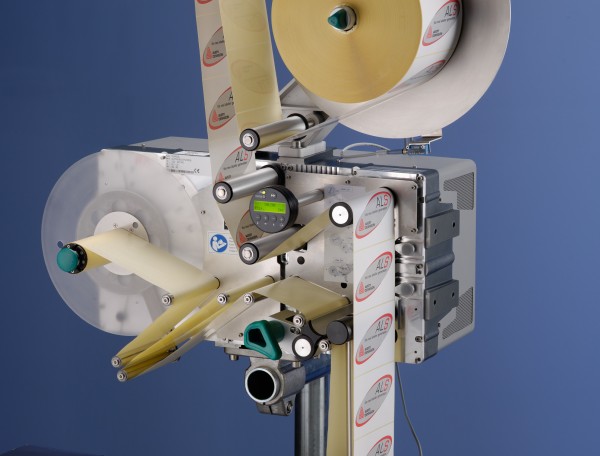

The ALS 306 & ALS 309 are the first of a truly unique range of modular label applicators. Their modular and robust concept allows high speed, wide labels and flexible integration – which makes them ideally suited for highly demanding industrial applications.When you acquire a new labelling machine, you want to make sure it fits in perfectly with your existing production line. This is exactly what the ALS 306 & 309 are designed to do. The label unwind unit can be mounted in any number of positions around the main machine body.

Top, left-side, right-side – wherever you need. Also, the machine can be integrated horizontally or vertically. Then, if you like, add a second label unwind unit, so that a new label roll is already there, ready to use when the other one is empty.

There’s another great aspect about the modular concept. What do you usually do when it comes to maintenance? You remove the back part of the body cover. With the ALS 306 & 309, the apply unit module and the powered rewind module can easily be pulled out, allowing front access also. So you’re much more flexible in your maintenance. Which means more up-time for the production line. Of course, you’re still free to remove the back part if you want to!

Offering new possibilities

Solid Performance

The ALS 306 can manage application speeds of up to 60 metres per minute – or, in other words, up to 1,000 labels per minute. High accuracy is assured, even at high speed – by the push-pull system that keeps the web tension constant, an essential pre-requisite for highly demanding product lines that run 24/7.

Automatic Product Speed Following (APSF)

Useful for conveyor belts with variable speeds: The optional APSF module calculates the product speed and changes the dispensing speed on-the-fly, ensuring the ALS 306 & 309 always keep up with the pace!

Flexible Intelligence

The ALS 306 & 309 are smart machines. They have an internal early warning system that informs the operator when to supply new labels, before they run out. They also deliver maintenance information, for example when a new dust filter is needed. Additionally, the firmware for the CPU board is upgradeable. This means new features can be added to extend the functionality and meet your labelling requirements as they change.

High Connectivity

The machines offer all common connectivity options: ethernet, serial port, USB, CF (Compact Flash) – and that’s all as standard!

User Friendly

All parameters can be edited using the built-in control panel, stored and recalled. Set it up once – and go. An additional remote control display is available to enable even more user-friendly access. You can then easily edit all parameters from a distance or from either side of the line.