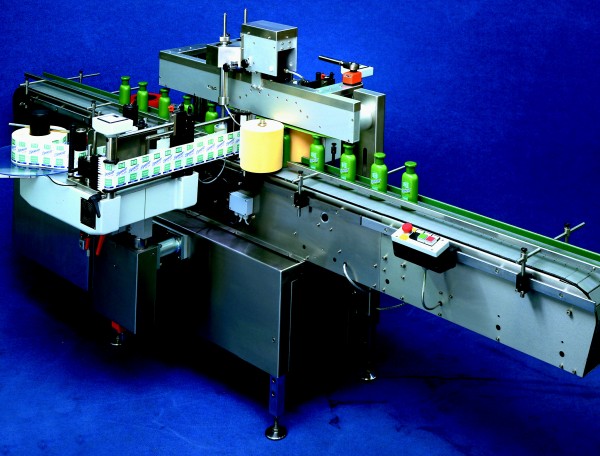

In-line Wrap-around or Front/Back Bottle Labelling

Designed and built for continuous wraparound or front/back labelling, the ALS 600 is a heavy-duty stainless-steel framed in-line labeller, for use in high volume production environments.

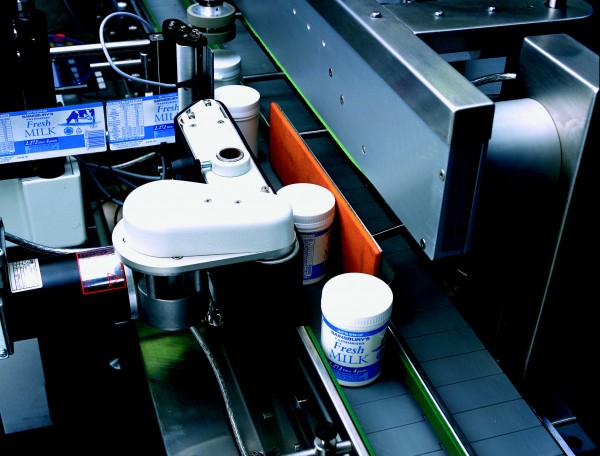

Products are transported directly from your filling and capping process machinery or placed manually on the main conveyor. A product separation wheel or motorised scroll unit, spaces the products out, to ensure that each product will be detected for reliable labelling. For oval-shaped products the ALS 600 can be equipped with the optional alignment unit, which adjusts each product in an accurate position. Flat and uniform cylindrical products can be guided and aligned by the product guides. Once the products have been aligned in this way, they are gripped under the hold down conveyor and secured in this position for the entire labelling process.

Once a product is below the hold down conveyor, it is detected by a photocell. This photocell triggers the labelling heads to apply the labels when the product passes the dispensing edges. By means of foam rollers the attached labels are sealed down for a perfect finish.

The hold-down conveyor on the ALS 600 is mechanically chain-linked to the main conveyor, which means there is no possibility of running out of sync, so the product is guaranteed to be perfectly stable when the label is applied. Hold-down conveyors that use a separate motor can sometimes struggle to keep in sync with the main conveyor and therefore can destabilise the product as they get labelled – with the ALS 600, this can never happen.

Easy to adjust, making it simple and reliable for long runs

The mechanical settings required can be set in a very convenient and reliable way. By the use of lead screws with digital position indicators, a repeat setting according to different product shapes and sizes can easily be carried out.

The required labelling head positions can be fine tuned accurately, in all directions during operation, thus ensuring outstanding labelling accuracy. The dispensing edges can also be exchanged quickly.

Fit with the ALS labelling heads of your choice

The ALS 600 has a flexible modular design, which allows the installation of all ALS labelling heads, and the print & apply ALX 730.

If different dispensing edges are required for your product there is a quick exchange device. This device allows different kinds of dispensing edges to be fitted to the labelling heads very efficiently.